By: Harkins Senior Estimator JD Reynolds

Harkins’ Preconstruction Department set out over 15 years ago to differentiate ourselves in the industry by developing a process that would streamline all aspects of construction and bring added value to the entire project lifecycle. Our Government Group realized the effectiveness of the RediCheck system, required on their projects, in identifying coordination and constructability issues and minimizing construction RFIs, delays, and costs, so we began to use that as our model and expand and adapt it to Harkins projects. We called our new process the Structured Plan Review (SPR).

The SPR begins when the construction documents begin to reach 75% – 90% completion. We call for an internal meeting of all team members on the project and add 5-10 Harkins employees who have expertise in the construction type or systems being used on the project. These additional team members bring fresh eyes to the project documents and may see things that may have been previously overlooked.

At the meeting, all project documents are uploaded to Bluebeam Studio, which creates a virtual, collaborative workspace. All team members are assigned different disciplines to review within the documents, based on their experience and skill set. Any items in question or of concern are noted. Ultimately, a list of RFIs is created from the comments on the documents and submitted to the design team prior to bid documents being issued.

The RFIs that are created from the SPR cover a wide variety of topics. They could be items as small as missing door tags or dimensions, which will save frivolous RFIs from being written during construction. Or they could uncover larger issues, such as missing footings, significant MEP coordination, etc.

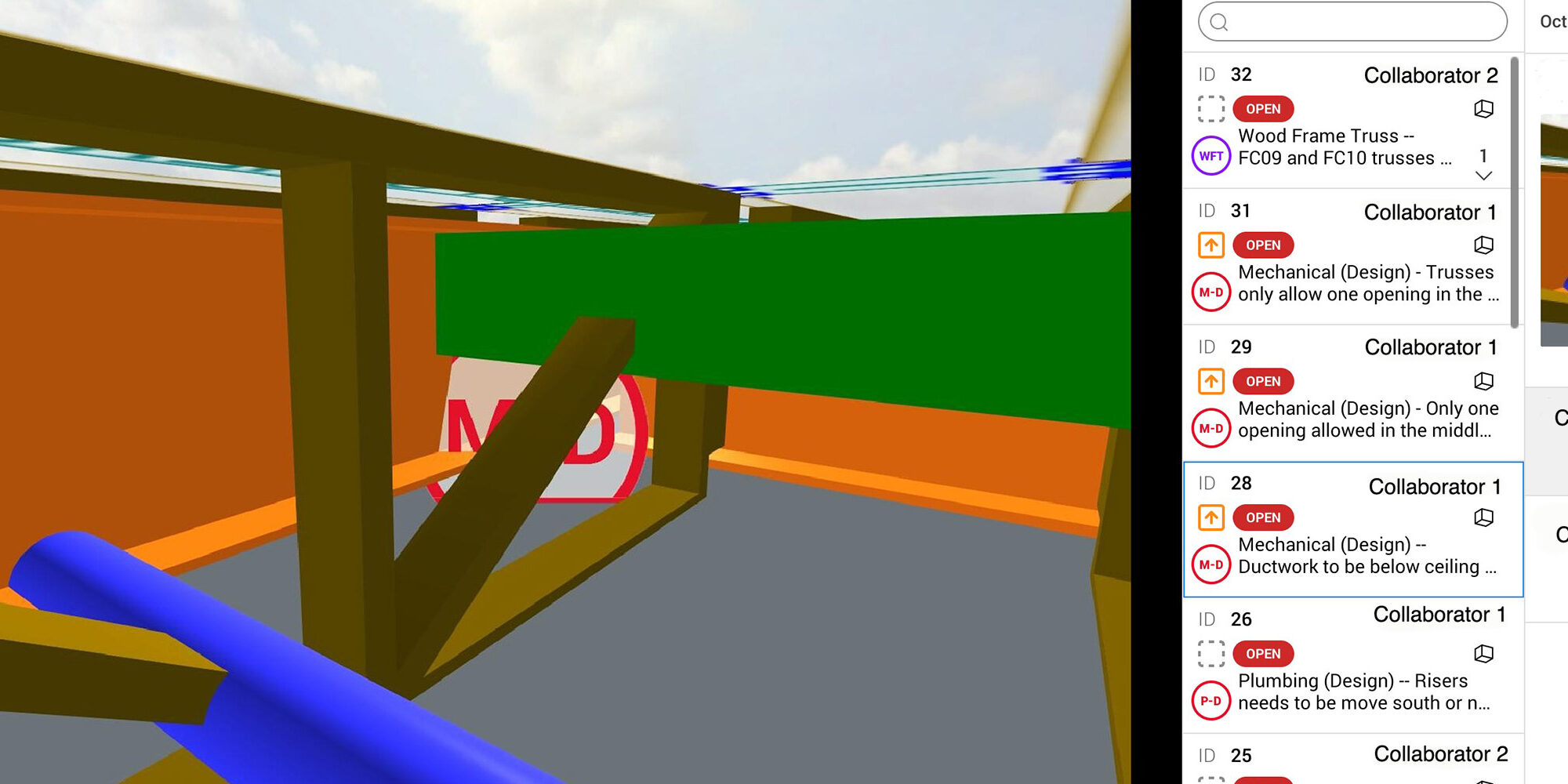

The SPR has evolved tremendously since its inception. We started incorporating BIM technologies when models are made available. One key aspect of the BIM model has been tagging coordination and clash detection issues (in Revizto) that are not as easily noticed during our 2D review. Taking BIM a step further, we have also incorporated 4D scheduling, where the team can see the model overlayed on the site plan and constructed according to the schedule. During this review, many site logistics issues are worked through, which saves time and money before we ever break ground.

The final step of the SPR is to deliver our findings to the design team and work collaboratively to ensure they are addressed in the documents prior to the bid process or breaking ground. The SPR is so effective at reducing coordination issues, RFIs, and time delays, that it creates a much smoother and cost-effective construction process. The SPR is an essential part of Harkins delivering our projects on time and under budget.

Continuous improvement is part of Harkins’ culture, and the SPR is no exception. To increase the leverage of collaboration, Harkins teams have begun to invite design team members to the Bluebeam Studio sessions so they can see, review, and comment on items and issues in real-time in one common space. Any issues or potential issues within the plans and specifications can be identified and immediately seen by the entire team. We hope this next step will help to identify more issues and allow them to be addressed at a faster pace, making the SPR and Harkins’ preconstruction process even more effective.

Header photo: Example screen from the Revizto Issue Tracker. The system has identified a clash between the wood frame truss, mechanical ductwork, and plumbing risers, which can be collaboratively tracked and resolved before construction. BIM technology has taken Harkins’ SPR to the next level of effectiveness.